Huma OsteoGelMA

Human Gelatin Methacrylate, Lyophilized

SKU: BMHL/BMML

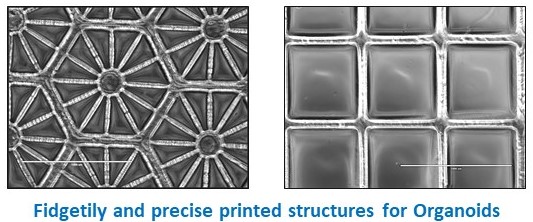

Huma OsteoGelMA is a methacrylated version of Humabiologics’ human bone gelatin, Huma OsteoGelatin, which is extracted from nutrient-rich human skeletal tissue sourced strictly from tissue partners who comply with the requirements of transplantable human tissue. Its ability to be photocrosslinked allows for a tunable 3D gel with a wide range of applications including 3D bioprinting, 3D culturing, and many other tissue engineering and regenerative medicine research applications.

Background

Product Description

Huma OsteoGelMA is a methacrylated version of Humabiologics’, first of its kind, human bone gelatin. Its ability to be photocrosslinked allows for a tunable 3D hydrogel with a wide range of applications including 3D bioprinting, 3D cell culturing, and many other tissue engineering and regenerative medicine research applications.

Note: requires a photoinitiator such as Irgacure 2959 or LAP.

Gelatin is a heterogenous mixture of water-soluble proteins with high average molecular masses. Gelatin is extracted by denaturing collagen-rich tissue in water [1]. The mechanical properties of gelatin, such as gel stiffness and compressibility, are related to the average molecular weight of the gelatin proteins and characterized by its Bloom number [2]. Humabiologics® offers the first and only human gelatin methacrylate in the market derived from bone at Bloom numbers between 90-300 g to meet the needs of translational research and regenerative therapies. Bloom number is proportional to the average gelatin molecular mass.

Due to its excellent biocompatibility, gelatin has been used to generate 3D scaffolds and hydrogels for tissue engineering applications [4] as well as a delivery material to control the release of bioactive molecules [5]. In the pharmaceutical industry, gelatin is used as an encapsulating agent and binder for tablet production [6]. Gelatin can be combined with other human-derived biomaterials- such as Collagen Type I from human skin (HumaDerm® offered by Humabiologics® ) – to make completely human-derived tissue engineered composites [7].

Tissue Source

Huma OsteoGelMA is isolated from human skin sourced strictly from American Association of Tissue Banks (AATB) accredited and FDA registered tissue banks and organ procurement organizations (OPOs). Humabiologics® strives to meet research needs by providing high quality biomaterials obtained from tissue partners who comply with requirements for transplantable human tissues under 21 CFR 1271 of the Food and Drug Administration (FDA).

Precautions and Disclaimer

Huma OsteoGelMA is obtained from human tissue that has been tested and found negative for minimum of HIV-1 and -2, hepatitis B, and hepatitis C, as well as other infectious agents. Please review the Safety Data Sheet (SDS) for information regarding hazards and safe handling practices. Huma OsteoGelMA is for research use only and is not intended for human use, diagnosis, screening, household, food or other uses.

Storage Conditions/Reconstitution

This product can be stored in airtight containers at ambient temperature (15-30 °C) upon receipt and prior to solubilization. Research grade products have a shelf life of 6 months upon receipt.

Huma OsteoGelMA can be reconstituted in 37°C PBS to the desired concentration with agitation/vortexing for several minutes. Dissolving time depends on the gelatin concentration but usually takes a few minutes for low concentration. Centrifugation might be used to remove undissolved particulate. After reconstitution, solution should be used immediately or stored at 2-10°C. Solubilized gelatin can be sterilized by filtration through a 0.22 µm membrane.

References

- Gelatin Manufacturers Institute of America Inc, Gelatin Handbook. 2012: 51 W 52nd St, New York, New York 10019, US.

- Gelatin Manufacturers Institute of America Inc, Standard Methods for the Sampling and Testing of Gelatins. 1986: 51 W 52nd St, New York, New York 10019, US.

- Davidenko, N., et al., Evaluation of cell binding to collagen and gelatin: a study of the effect of 2D and 3D architecture and surface chemistry. J Mater Sci Mater Med, 2016. 27(10): p. 148.

- Kang, H.W., Y. Tabata, and Y. Ikada, Fabrication of porous gelatin scaffolds for tissue engineering. Biomaterials, 1999. 20(14): p. 1339-44.

- Dong, Z., Q. Wang, and Y. Du, Alginate/gelatin blend films and their properties for drug controlled release. Journal of Membrane Science, 2006. 280(1): p. 37-44.

- Corveleyn, S. and J.P. Remon, Formulation and production of rapidly disintegrating tablets by lyophilisation using hydrochlorothiazide as a model drug. International Journal of Pharmaceutics, 1997. 152(2): p. 215-225.

- Gautam, S., et al., Surface modification of nanofibrous polycaprolactone/gelatin composite scaffold by collagen type I grafting for skin tissue engineering. Materials Science and Engineering: C, 2014. 34: p. 402-409.

Instructions for Use

Crosslinking

Note: The following are general recommendations. Researchers should optimize parameters based on their specific application.

- Dissolve Huma OsteoGelMA in 60°C 1x PBS or 1x cell culture media at the desired concentration. Recommended final concentration is ≥ 5%.

- a. Mechanical properties of the hydrogel can be controlled by varying the Huma OsteoGelMA concentration, the photoinitiator concentration, and degree of crosslinking.

- Dissolve photoinitiator and keep solution protected from light.

- a. Irgacure 2959 can be dissolved in neat methanol or DMSO at a 10% concentration.

- b. LAP can be dissolved in PBS at a 2.5% concentration.

- Add the desired amount of photoinitiator to the Huma OsteoGelMA solution. Depending on the application and bioprinting parameters, a photoinitiator concentration between 0.1 – 0.5% is recommended.

- In a sterile environment, use a syringe filter to sterile filter the Huma OsteoGelMA.

- Place sterile Huma OsteoGelMA in 37°C incubator.

- Add the cells to the sterile Huma OsteoGelMA/photoinitiator solution.

- Load the cell/Huma OsteoGelMA/photoinitiator solution into the bioprinting syringe specific to the bioprinter according to the manufacturer’s instructions.

- Set up bioprinter and optimize parameters based on the printing condition, intended application, and bioprinter manufacturer instructions. The parameters needing to be optimized include nozzle diameter, pressure, nozzle temperature, print bed temperature, print speed, and crosslinking light source distance and intensity.

- a. These are important parameters to optimize in order to achieve the desired extrudability of the Huma OsteoGelMATM from the nozzle. Good extrudability means the bioink flows out of the nozzle as a filament as opposed to droplets.

- b. Based on the photoinitiator used, crosslinking settings will vary.

- i. For LAP, the crosslinking light should be at a wavelength of 405

- ii. For Irgacure 2959, the crosslinking light should be at a wavelength of 365 nm.

Quality Testing

| Test | Specification |

|---|---|

| Appearance (form) | |

| Color | White |

| Form | Flaky Material to Powder |

| Solution Turbidity | Clear to Slightly Hazy |

| pH (6.67% in DI water) | Report |

| Cell Attachment | Pass |

| Immunology/Serology Testing* | |

| HBV | Non-Reactive |

| HCV | Non-Reactive |

| HIV-1 | Non-Reactive |

| HIV-2 | Non-Reactive |

| RPR-Syphilis | Non-Reactive |

*Testing was done using FDA approved kits in CLIA certified lab

** Donor information is available upon request

Publications

- Bedell, M., et al., Available at SSRN: https://ssrn.com/abstract=4174909 or http://dx.doi.org/10.2139/ssrn.4174909

- Bedell, M., et. al. 2022 Biofabrication 14 045012 doi: 10.1088/1758-5090/ac8768

- Sylvester, C., et al., (2023). Frontiers in Cardiovascular Medicine. doi:10. 10.3389/fcvm.2023.1112965

- Mine Altunbek, Mert Gezek, Paige Buck, and Gulden Camci-Unal Biomacromolecules 2024 25 (1), 165-176 DOI: 10.1021/acs.biomac.3c00894

Safety Data Sheet